Share

Automotive tapered shock absorbers

Product Category:

Keyword:

- 产品描述

-

Shock absorbers primarily control the oscillation of springs after shock absorption and impacts from the road. While shock-absorbing springs filter road vibrations, they themselves undergo reciprocating motion. Shock absorbers suppress this spring bounce. If shock absorbers are too soft, the vehicle body will bounce up and down; if they are too hard, they will create excessive resistance, hindering the normal function of the springs. Shi Xiaohui indicated that in suspension system modifications, hard shock absorbers should be paired with hard springs. Spring hardness is closely related to vehicle weight; therefore, heavier vehicles generally use harder shock absorbers. Modifications require continuous experimentation to design optimal shock absorber and spring combinations. Professional modification shops can usually help car owners find suitable pairings.

1. Check if the product offers a 2-3 inch lift requirement. Some products only offer a 2-inch lift, and forcing them to 3 inches can easily cause damage during off-roading.

2. Ensure the shock absorber's central telescopic rod diameter is 16mm or more. This is a basic indicator of strength.

3. Verify that the upper and lower connecting sleeves of the shock absorber are made of high-strength polyurethane. This is crucial for ensuring long-term, high-intensity use, as ordinary rubber cannot withstand high intensity for extended periods.

Shock absorbers are easily damaged parts in vehicle use. Their proper functioning directly affects the vehicle's smooth operation and the lifespan of other components. Therefore, we should ensure shock absorbers are always in good working condition. The following methods can be used to check if the shock absorbers are working properly.

1. Drive the vehicle on a relatively rough road for 10km, then stop and touch the shock absorber casing. If it's not hot, it indicates a lack of internal resistance, meaning the shock absorber is not working. In this case, add appropriate lubricating oil and retest. If the casing heats up, it means the shock absorber lacks oil and needs to be refilled. Otherwise, the shock absorber has failed.

2. Push down firmly on the bumper and release it. If the vehicle bounces 2-3 times, the shock absorbers are working properly.

3. When the vehicle is slowly driving and brakes suddenly, significant vibration indicates a problem with the shock absorbers.

4. Remove the shock absorber, stand it upright, and clamp the lower connecting ring in a vise. Pull and push the shock absorber rod several times. There should be stable resistance, with upward resistance greater than downward pressure. Unstable or no resistance may indicate a lack of oil or damaged valve parts inside the shock absorber, requiring repair or part replacement.

If a shock absorber problem or failure is confirmed, check for oil leaks or signs of old oil leaks.

If there are no oil leaks, check for damage, welding defects, cracks, or detachment in the bushings. If the above checks are normal, further disassemble the shock absorber to check for excessive clearance between the piston and cylinder, cylinder scratches, proper valve sealing, tight valve and seat fit, and whether the shock absorber extension spring is too soft or broken. Repair or replace parts as needed based on the condition of the shock absorber connecting pin, connecting rod, connecting hole, and rubber.

Additionally, shock absorbers may make noise during use. This is mainly due to collisions between the shock absorber and the leaf spring, frame, or axle; damaged or detached cushions; deformed shock absorber dust boots; or insufficient oil. The cause should be identified and repaired.

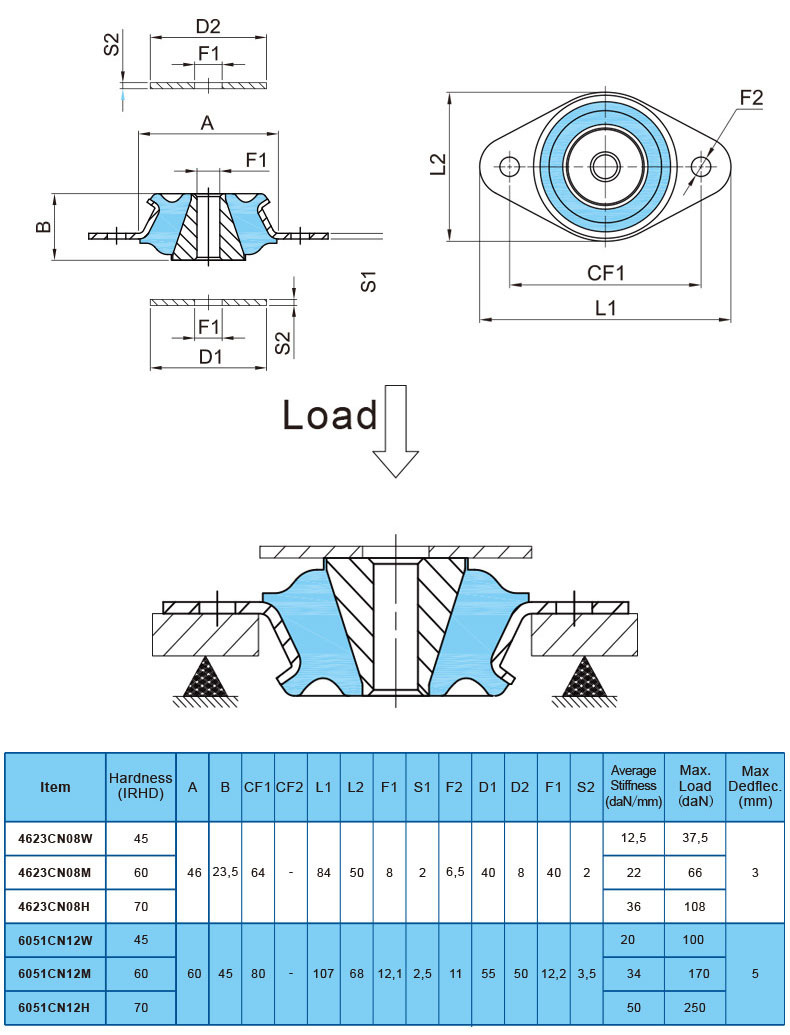

After inspection and repair, shock absorbers should undergo performance testing on a specialized test bench. When the resistance frequency is 100 ± 1mm, the resistance of the extension and compression strokes should meet the specifications, indicating that the shock absorber is functioning properly.These shock absorbers have a special rubber cross-section for shear and compression loading, allowing for good axial displacement. The bracket is a low-cost isolator with high load capacity in a compact size, providing a solution for a wide range of applications. This mounting is ideal for trucks, car engines, radiators, etc. The cab mount is equipped with two safety washers to prevent overloading. CN A version features two different radial stiffnesses.

Application Areas

Generator Sets

Engines

Compressors

Special Equipment

Pumps

HVAC (Heating, Ventilation, and Air Conditioning)

Production Standards

Material: DD 13 (pickled plate) & DC04 (cold-rolled steel) Q/BQB403-2003

Natural Rubber/Synthetic Rubber

Surface Treatment: Galvanized

According to customer requirements

Stiffness Tolerance: +/-15%

Additional Parts

Hardness and material options

Why Choose Us

Kaiping Jianqiao Sealing Technology Co., Ltd.

Kaiping Jianqiao Sealing Technology Co., Ltd. was established in 2006. It is a professional company engaged in the research, development, production and sales of screw dampers, rubber dampers, rubber shock absorbers, rubber damping pads, silicone rubber products and plastic products. The company has been committed to rubber and metal bonding technology for many years, especially in the application of shock absorption, wear resistance and sealing in the industry, and has established long-term cooperation with major domestic manufacturers. Company products are mainly used in automotive, home appliances, pneumatic sealing, hydraulic sealing, engineering machinery and other industries. Our company actively absorbs the experience of our peers and continuously improves product quality. The products of the supporting manufacturers are exported to many countries and regions. South China University of Technology and Guangzhou Rubber Industry Research Institute provide long-term technical support, and the product quality is continuously improved. The screw (nut) pads in the products are deeply loved by manufacturers, the monthly output of small oil seals used for pneumatic support exceeds one million, and the monthly output of Y-rings and O-rings used for hydraulic hinge small oil cylinders reaches eight million. Langqiao has established long-term cooperative relationships with well-known domestic enterprises such as Gree, Zhigao, Guangzhou Micro Motor Factory Co., Ltd., and Guangzhou Wensui Plastic Machinery Co., Ltd.

Founded in 2006

More than 16 years of industry experience

Exporting countries and regions

Monthly production capacity

Manufacturing Technology

Taking intelligent manufacturing technology as its core competitiveness, it has built a high-precision technology matrix covering R&D, production, and testing. The company is equipped with an image measuring instrument and an automated visual inspection machine VV08-2000, realizing intelligent identification of micron-level size and surface defects of rubber parts; relying on multifunctional material testing machines and rotorless vulcanization machines to precisely control rubber formulas and vulcanization processes, ensuring product aging resistance and fatigue resistance performance; through precision salt spray testing machines to simulate extreme environments, verify the long-term stability of seals under corrosion and high and low temperature conditions. At the same time, the collaborative application of the cold-freezing trimming machine RM-100L and the conveyor-type automatic sandblasting machine XTS650-9B gives products a burr-free, high-cleanliness industrial-grade surface treatment standard, meeting the strict requirements of the automotive and precision machinery industries for "zero defect" shock-absorbing seals, and empowering customers' product reliability upgrades with hard-core intelligent manufacturing technology.

undefined

FAQ

Automotive tapered shock absorbers

Product Category:

Keyword:

Product Inquiry

Note: Please leave your email and mobile phone number, and our professionals will contact you as soon as possible!

Contact Us

Address: No. 1, Longfa Road, Longsheng Town, Kaiping City, Guangdong Province

Website: www.jmjianqiao.com